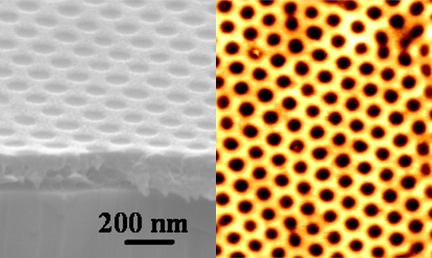

The group is currently undertaking a number of different projects, all revolving around the theme of surface structuring and patterning. Patterning is achieved using block copolymers which can be controlled to produce periodic arrays of lines, triangular lattices and other geometries. Either polymer can be infiltrated with another material, e.g. a metal for an etch mask or for plasmonic applications, and the polymer subsequently removed or kept depending on the desired function.

The group has expertise in different areas of chemistry and physics:

- Block CoPolymers

The group has mostly considered di-block copolymers for the preparation of favourable patterns. Di-BCPs are formed by chemically connecting two polymer chains. Under certain conditions, the polymers can phase separate into periodic arrangements. These arrangements can be maintained over areas of centimetres and larger and can be designed to contain feature sizes below 100 nm.- Surface structuring with physical etching

- Structuring surfaces is achieved by inductively coupled plasma (ICP) etching. This physical method provides control over the height and shape of the resulting structures and is used for etching different materials—BK7 glass, silicon.

- Optics and plasmonics

- The feature size of BCP patterns is suitable for sub-wavelength optics and the ability to produce these patterns on large substrates (upwards of a square inch) surpasses typical methods for producing such structures, such as electron beam lithography. With fine control of the surface structure, the reflectivity of a substrate can be reduced; a surface pattern of nanoscale metallic particles creates a metasurface which exhibit properties unachievable with regular materials; tailored plasmonic absorption can also be achieved with these structures.

Selected Publicity and Publications

- Large Block Copolymer Self-Assembly for Fabrication of Subwavelength Nanostructures for Applications in Optics, Nano Letters, 17 (5) 2973–2978, 2017. URL

- Abrasion resistant surfaces on the Trinity College website.

- Report on SUN-PILOT in the Irish Times.